Block wool

2022 –

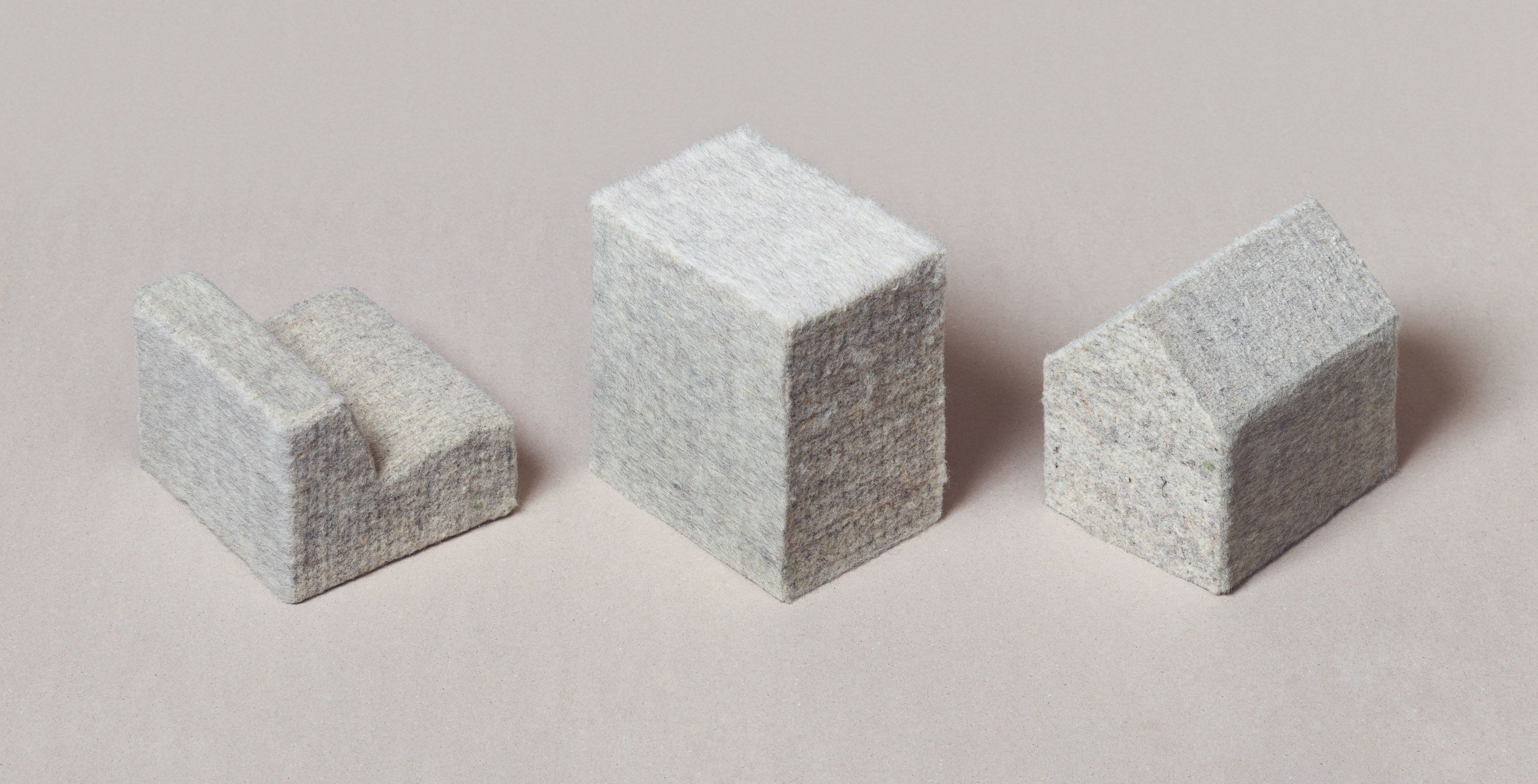

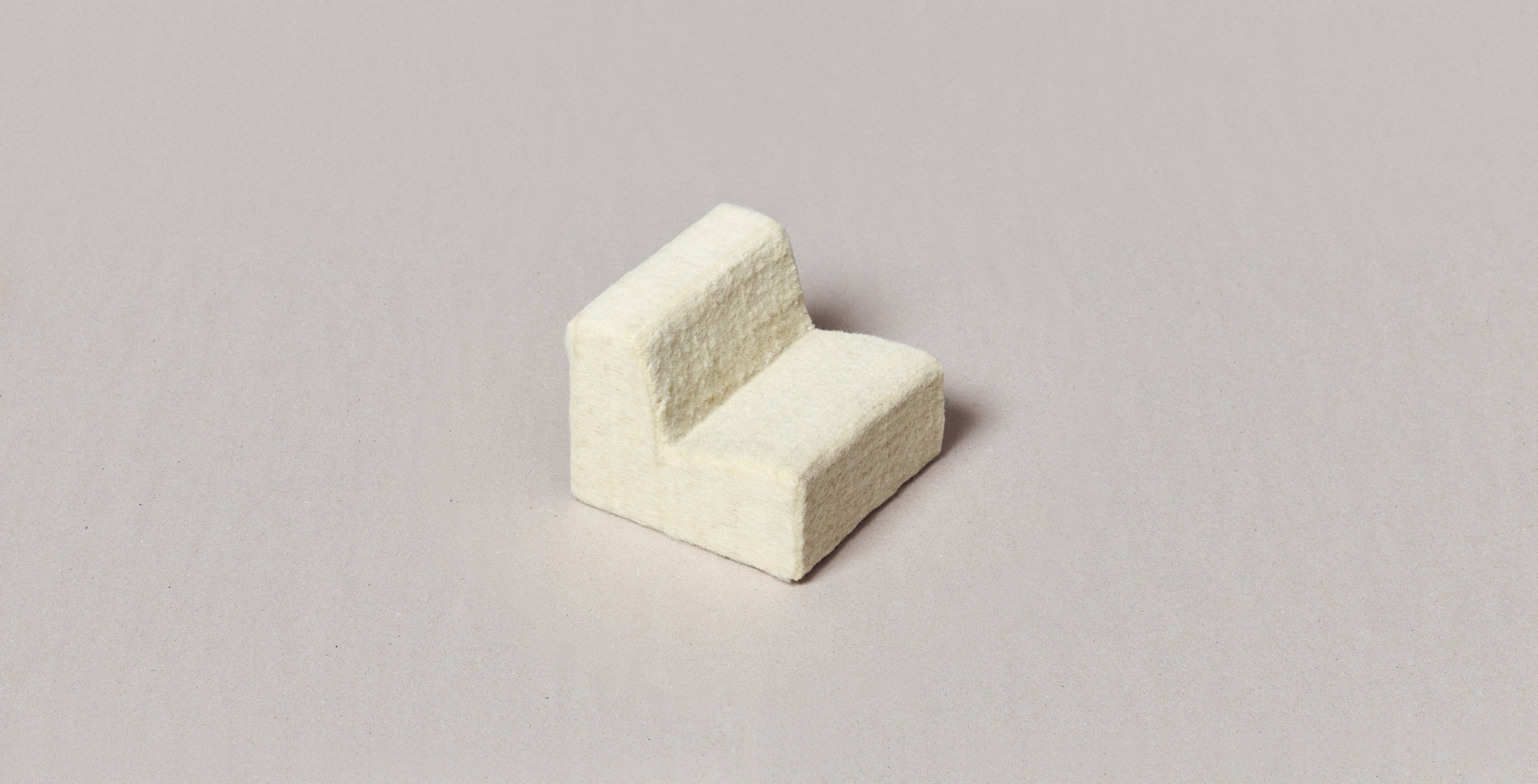

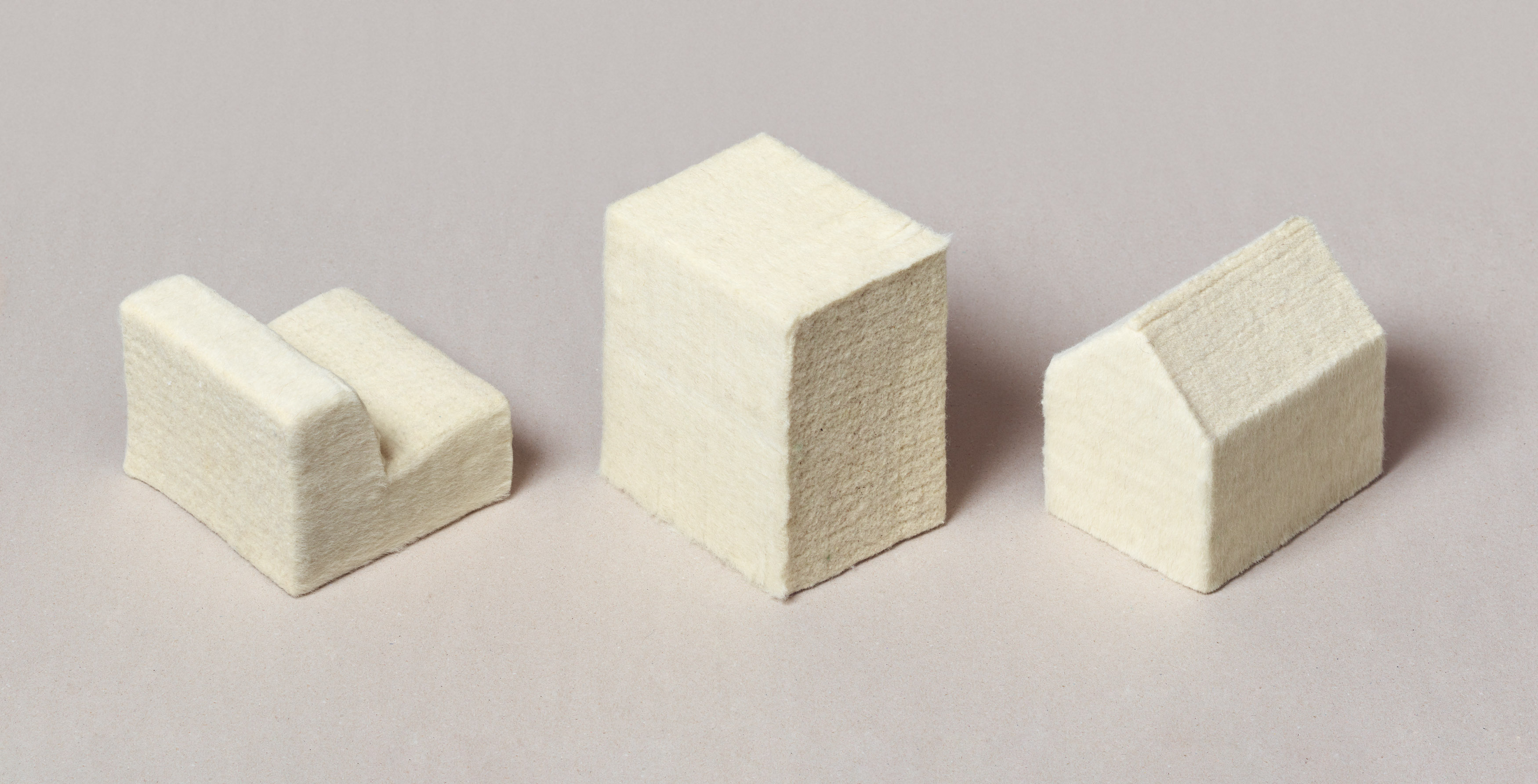

The new Block wool is made with a custom developed production technique to make wool in blocks without additives or binders. The technique is especially meant to find a purpose for local wool from local herds, starting with the ‘Kempisch Heideschaap’ - a sheepbreed local to the Southern part of the Nethrlands - and to find substitutes for materials such as foam rubber, glass wool, stone wool and polystyrene foam.

The project is a follow up of the Zachte Stad; a research project commissioned by Rotterdam Circulair about finding out what was the quality and value of the wool of the Rotterdam herd of sheep - closely related to the Kempisch Heideschaap - and owned by Martin Oosthoek. After the project Meindertsma felt there was a need for a new technique that would make it possible to build wool in truly three-dimensional shapes without limits in size. Two techniques are being developed at the same time. One is the Wobot, a cobot that is developed for creating 3D free felted forms, the other is a new ‘Block wool’ machine that can create blocks of wool that can be cut to shape.

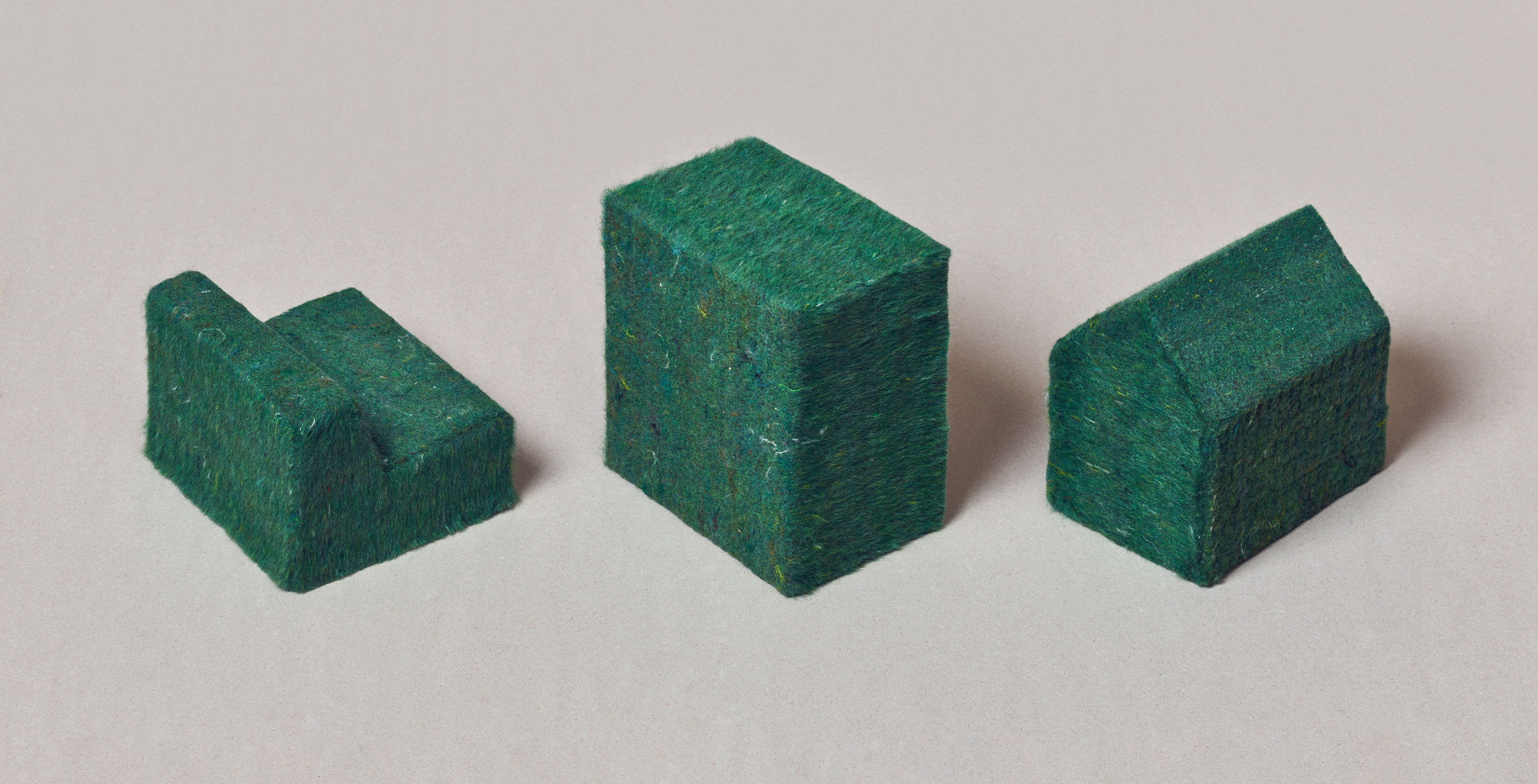

Besides

using natural virgin wool, it is also possible to blend the wool with recycled wool to add

color and create a rich color palette. Tests have been made in collaboration

with the local Gelderland furniture factory, using the colorful woolen off-cuts

collected from their production process; surprisingly even a fully recycled wool block was possible.

Link: Dinamofonds

CREDITS: Kuperus & Gardenier, Havivank

MADE POSSIBLE BY:

Dinamofonds, Cuypershuis, Gelderland and De Wassum.